January 20, 2026

Small manufacturers operate in highly competitive environments where efficiency, consistency, and reliability directly affect long-term success. Equipment performance often determines whether production goals are met or missed, especially when margins are tight and resources are limited. Among the many systems that support manufacturing operations, vacuum technology plays a critical but sometimes overlooked role. Understanding how this equipment supports daily operations can help manufacturers make smarter investment decisions. When properly selected and maintained, this type of equipment can significantly improve workflow, quality control, and operational stability. These advantages can make a measurable difference in how small manufacturers compete within their industries while maintaining operational control. Over time, dependable systems also support stronger planning, workforce confidence, and sustainable production growth.

Understanding the Role of Vacuum Technology

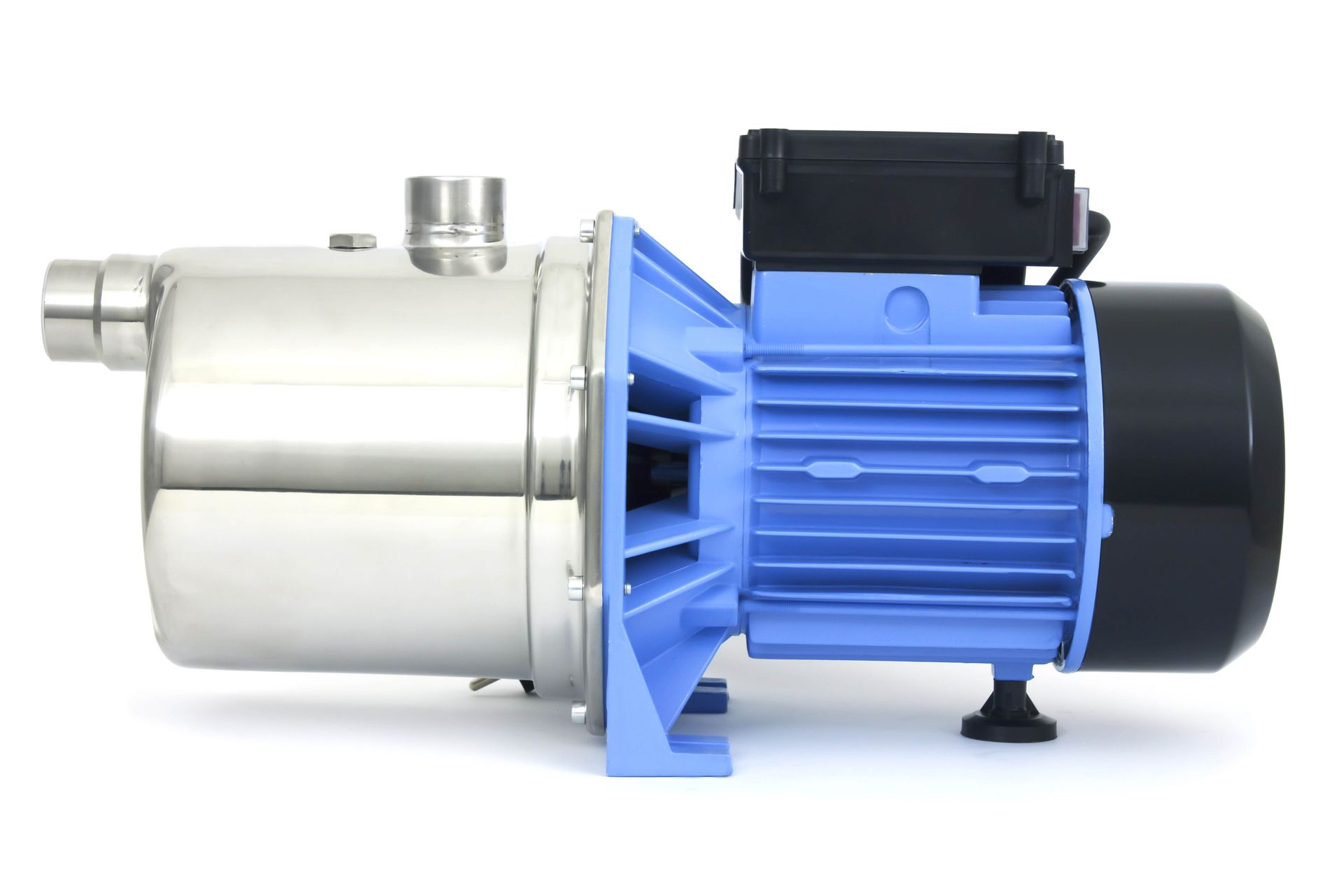

Vacuum systems are essential in many manufacturing processes, including material handling, packaging, forming, and drying applications. A vacuum pump creates controlled pressure environments that allow equipment to function efficiently and consistently. For small manufacturers, this consistency is especially important because downtime can disrupt entire production schedules. Reliable vacuum performance helps maintain product quality while minimizing waste and rework. Over time, dependable equipment contributes to smoother operations and stronger customer satisfaction. This reliability becomes a foundation for maintaining steady production standards.

For small operations, a vacuum pump plays a direct role in maintaining a steady production flow. Equipment that operates reliably allows employees to focus on output rather than troubleshooting issues. When vacuum pressure remains stable, processes such as sealing, lifting, or forming materials can be completed faster and more accurately. This efficiency helps small manufacturers compete with larger operations without significantly increasing overhead. A well-functioning system also reduces unnecessary stress on other machinery. Improved efficiency often leads to more predictable production outcomes.

Reducing Unexpected Downtime

Unexpected equipment failure can be especially damaging for small manufacturers with limited staffing and tight production windows. A properly maintained pump reduces the likelihood of sudden breakdowns that halt operations. Preventive maintenance and timely repairs help identify worn components before they lead to larger issues. Consistent system performance allows production schedules to remain predictable. This reliability supports better planning and helps maintain strong relationships with customers. Fewer disruptions also improve overall workplace morale.

Many manufacturing processes depend on precise pressure control, which is where a pump becomes critical. Inconsistent pressure can lead to defects, poor sealing, or uneven forming. Quality issues not only waste materials but also damage a manufacturer’s reputation. Reliable vacuum performance ensures that products meet specifications batch after batch. Over time, improved consistency helps small manufacturers build credibility within their markets. Strong quality control can also lead to repeat business and referrals.

Addressing the Needs of Small Manufacturers

Small manufacturers often operate with fewer resources than large corporations, making equipment reliability even more important. According to the U.S. Small Business Administration, 98% of manufacturing firms in the U.S. are small businesses. This highlights how critical dependable machinery is across the manufacturing sector. A vacuum pump that performs consistently supports growth without requiring constant reinvestment. Reliable equipment helps small manufacturers remain competitive while managing operational costs effectively. This stability allows owners to focus on strategic improvements.

Pump rebuilding offers small manufacturers an effective way to extend the life of existing equipment. Instead of replacing an entire system, rebuilding restores performance by replacing worn or damaged components. This approach helps manufacturers maintain reliable operations while managing expenses. A rebuilt pump can perform comparably to a new unit when handled by experienced professionals. This option supports sustainability while maintaining operational stability. Rebuilding also minimizes production interruptions associated with equipment replacement.

Managing Costs Without Sacrificing Performance

Balancing performance and budget is a constant challenge for small manufacturers. Investing in a quality pump helps reduce long-term costs associated with inefficiency and frequent repairs. Rebuilding and repair services provide cost-effective alternatives to full replacement. Competitive pricing allows manufacturers to maintain high standards without overextending budgets. Over time, this balance supports healthier financial planning and operational growth. Controlled costs contribute to long-term business resilience.

Fast turnaround times are essential when critical equipment requires service. A vacuum pump that is repaired or rebuilt quickly minimizes production delays. Small manufacturers benefit greatly from service providers who understand the urgency of keeping operations running. Efficient repair timelines help prevent backlog and missed deadlines. Quick service ensures that production resumes with minimal disruption. Speedy repairs help protect customer commitments and delivery schedules.

Supporting Diverse Manufacturing Applications

Manufacturing environments vary widely, and a pump must adapt to different applications. From packaging to material handling, consistent pressure control is essential across multiple processes. Repair and rebuilding services help tailor equipment to specific operational needs. This flexibility allows small manufacturers to diversify their offerings. Adaptable vacuum systems support growth and changing production demands. Versatile equipment also reduces the need for multiple specialized systems.

Routine maintenance plays a key role in keeping a pump operating efficiently. Regular inspections and timely repairs prevent small issues from becoming major failures. Simplified service processes help manufacturers stay focused on production rather than equipment management. Repair services that prioritize clarity and efficiency reduce downtime. This proactive approach supports long-term reliability and operational confidence. Clear maintenance planning also helps avoid unexpected service costs.

Expanding Access Through Nationwide Shipping

Nationwide shipping available for vacuum pump services allows small manufacturers to access specialized support regardless of location. This accessibility ensures consistent service quality without geographic limitations. Manufacturers can receive repairs, rebuilding, or replacement units without extended delays. Shipping options support continuity of operations even in remote areas. Expanded access helps level the playing field for smaller operations. Reliable logistics reduce downtime caused by transportation challenges.

Reliable vacuum systems allow small manufacturers to plan production schedules with confidence. A pump that performs consistently supports accurate forecasting and workflow management. This stability helps reduce stress for both employees and management. Long-term planning becomes more achievable when equipment reliability is assured. Strong operational planning supports sustainable growth. Predictable equipment performance enables better staffing and inventory decisions.

Enhancing Workplace Safety and Reliability

Equipment failures can pose safety risks in manufacturing environments. A properly functioning vacuum pump helps reduce hazards associated with pressure inconsistencies or mechanical failures. Routine repair and rebuilding services contribute to safer working conditions. Improved reliability supports employee confidence and productivity. Safety-focused operations strengthen overall business performance. A safer environment also supports compliance with workplace health and safety standards.

As small manufacturers grow, dependable equipment becomes even more critical. A pump that scales with production demands helps prevent bottlenecks. Rebuilding, repair, and sales services provide flexible options as needs evolve. Reliable systems support expansion without excessive capital investment. This adaptability encourages steady, manageable growth. Scalable equipment allows businesses to respond quickly to new opportunities.

The impact of reliable vacuum technology on small manufacturing operations cannot be overstated. Consistent performance, reduced downtime, and manageable costs all contribute to stronger daily operations and long-term success. Vacuum Pump Rebuilders supports small manufacturers through pump rebuilding, repair, and sales, offering fast turnaround times, competitive prices, and nationwide shipping. By focusing on reliability and efficiency, manufacturers can maintain productivity while planning for future growth. Quality equipment support also helps protect product standards, employee safety, and operational confidence as businesses evolve. Investing in dependable vacuum systems allows small manufacturers to remain agile, resilient, and prepared for changing production demands. For more information, contact us today!