December 18, 2025

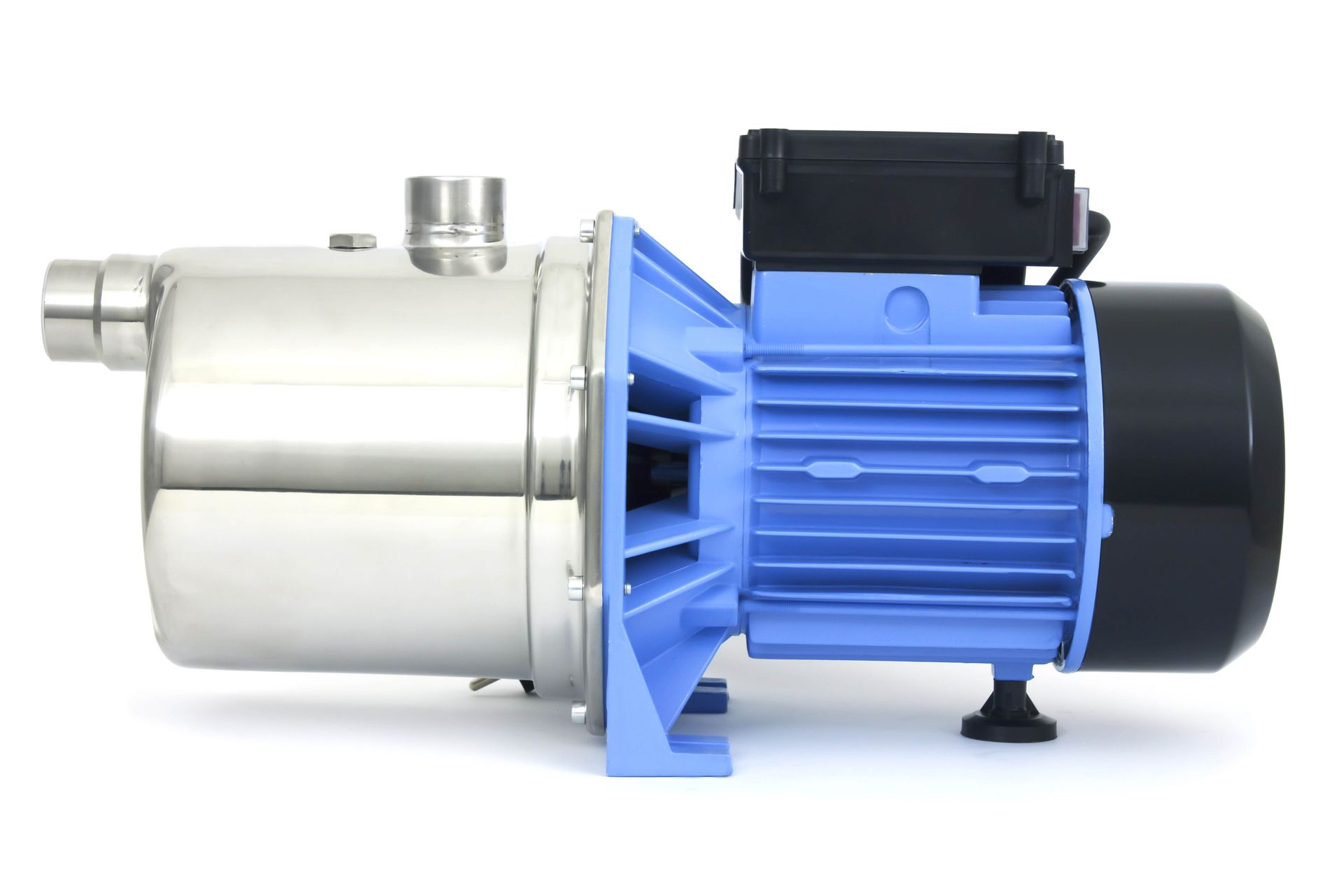

Vacuum pumps are indispensable tools in various industries, enhancing efficiency, performance, and safety in countless applications. A high-quality vacuum pump can make a substantial impact across sectors, from manufacturing to healthcare. Let's take a moment to explore a few ways these advanced devices can transform operations and deliver measurable benefits.

1. Improved Process Reliability

High-quality vacuum pumps are pivotal in ensuring consistent reliability in industrial processes, reducing downtime, and maintaining productivity levels. By providing stable performance, these pumps minimize disruptions in production lines, thus enabling a smooth workflow. The reliable operation of these pumps translates to fewer unexpected halts, allowing industries to meet their output targets efficiently. Industries reliant on precise environmental control, like semiconductor manufacturing, especially benefit from this reliability, resulting in fewer product defects. As operational consistency is paramount, having robust vacuum technology in place ensures that businesses can maintain their competitive edge.

2. Faster Processing Times

By optimizing vacuum levels quickly, superior pumps accelerate various manufacturing processes, thus enhancing overall production speed. Their capacity to achieve desired vacuum states expediently reduces waiting times in processes, such as drying and coating. This increased pace directly contributes to higher throughput, which is vital for industries aiming to maximize production efficiency. Faster cycles not only improve profitability but also decrease the time-to-market for new products. In a market where speed is a differentiating factor, leveraging high-quality vacuum pumps provides a strategic advantage.

3. Reduced Energy Consumption

Advanced vacuum pumps are designed to consume less energy, leading to cost savings and a lower carbon footprint during operation. These energy-efficient technologies harness innovations that reduce overall power usage while maintaining optimal performance. Some pumps utilize state-of-the-art electronics and materials that deliver high efficiency with minimal waste. The integration of such devices aligns organizations with global sustainability goals, thus enhancing their corporate social responsibility profiles. As the U.S. vacuum pump market is expected to reach a valuation of $4.1 billion in 2035, according to Fact.MR, energy-efficient solutions will likely be a major contributing factor to growth.

4. Minimal Maintenance Needs

The robust construction of high-quality vacuum pumps minimizes wear and tear, thereby reducing the frequency and cost of maintenance activities. These durable pumps are engineered with high-grade materials that withstand harsh conditions, extending their operational life. With fewer breakdowns and lower maintenance requirements, businesses can allocate their resources more effectively. This reliability also means fewer disruptions in production, which keeps costs down and maintains output levels. In industries where maintaining operational continuity is critical, these pumps offer invaluable support by consistently performing under demanding conditions.

5. Enhanced Scalability Options

A premium vacuum pump provides scalable solutions that adapt to growing production needs, facilitating seamless business expansion. Their capacity to integrate with existing systems makes it easy for companies to increase their operational scope without overhauling their infrastructure. As businesses grow, the need for equipment that can handle higher loads becomes apparent, and high-quality pumps meet this demand efficiently. Additionally, their flexible configurations allow for customization to meet specific needs, ensuring maximum utility. These scalable features make premium vacuum pumps not just a tool, but a strategic investment for future growth.

6. Precision Control in Applications

With accurate control over vacuum levels, high-quality pumps ensure the precision required for high-quality product outcomes. This is especially crucial in industries like pharmaceuticals and food processing, where quality control is stringent. Premium pumps are equipped with advanced control systems that allow exact adjustments to match specific application requirements. Consistently achieving optimal conditions means reduced variability in product batches, significantly enhancing product quality. This level of control helps businesses meet regulatory and consumer standards, thereby sustaining their market reputation.

7. Reduced Contamination Risks

Advanced sealing and filtration techniques in these pumps minimize contamination, safeguarding the integrity of sensitive products. Seals are crafted from superior materials that provide an effective barrier against contaminants, essential in cleanroom environments. These pumps also incorporate multi-stage filtration systems that capture impurities, ensuring only clean air interacts with the process materials. By maintaining high purity levels, they are integral in processes that demand extreme cleanliness, such as electronics manufacturing. This reduction in contamination risk enhances product reliability, thereby building customer trust and satisfaction.

8. Consistent Product Standards

A high-quality pump maintains stable operating conditions, essential for achieving uniform product quality and meeting industry standards. The ability to consistently hold precise vacuum levels ensures that each production cycle meets predetermined specifications. Industries dealing with materials that require specific atmospheric conditions, such as plastics or ceramics, witness fewer defects when using reliable vacuum pumps. By maintaining these standards, businesses can ensure compliance with international guidelines, necessary for competitive positioning. Ultimately, this consistency leads to a reduction in waste and an increase in profitability.

9. Streamlined Moisture Removal

Efficient moisture evacuation is critical to many processes, and a premium vacuum pump excels in removing unwanted moisture rapidly. Moisture can significantly compromise the quality of products in industries such as paper manufacturing and electronics. High-performance vacuum pumps are designed to swiftly remove moisture from delicate products, ensuring they do not degrade during processing. The ability to maintain low humidity conditions minimizes the risk of defects, thus ensuring the end product's highest quality. Through effective moisture control, companies can achieve smoother operations and reduced processing times.

10. Enhanced Vacuum Precision

These pumps provide superior vacuum precision that is crucial for delicate processes, such as freeze-drying or chemical synthesis. Such precision ensures that critical thresholds are not breached, which could otherwise compromise the product. The capability to finely tune vacuum levels is vital for processes that rely on meticulous environmental conditions. This ultimately supports the creation of products with intricate compositions, without compromising on quality or efficacy. By adopting high-precision pumps, companies can continually innovate and develop advanced products that meet the evolving needs of their markets.

11. Reduced Waste Emission

Eco-friendly vacuum pumps are engineered to release fewer waste products, aligning with stringent environmental regulations. By reducing emissions during operations, these pumps help industries comply with environmental laws and reduce their ecological impact. Their design incorporates technologies that minimize off-gassing and other harmful emissions. This ensures that businesses not only meet compliance requirements but also support broader sustainability goals. In an age where environmental accountability is increasingly critical, adopting such technology showcases a corporate commitment to a greener future.

12. Lower Energy Footprint

Employing an energy-efficient vacuum pump can significantly contribute to reducing the overall energy footprint of operations. Technologies such as variable speed drives and high-efficiency motors enable pumps to use power judiciously, only operating at full power when required. This targeted energy use results in substantially lower electricity bills and operational costs, crucial for businesses focused on sustainability. As environmental standards become stricter, leveraging technologies that inherently consume less energy positions companies favorably in the marketplace. Additionally, a reduced energy footprint often translates to enhanced corporate reputation in environmentally-conscious markets.

Investing in a high-quality vacuum pump can lead to significant advances in production efficiency, product quality, environmental sustainability, and economic performance. The versatility and robust design of these pumps make them an essential component of modern industrial operations. By aligning their use with strategic objectives, businesses can harness their full potential and achieve long-lasting benefits. If you're interested in taking advantage of all the benefits a quality vacuum pump can offer, reach out to Vacuum Pump Rebuilders. We can get you started today with a free same-day estimate!